ISO13997 – Cut Resistance

ISO13997 is the second cut level test under EN388 (mechanical hazards); introduced in the 2016 revision of the standard. In a nutshell, the test reflects the force required to cut through the product being tested, giving a fair reflection of the strength of a glove.

The performance level is referenced as the fifth digit under the EN388:2016 shield, as shown to the right. This test need only be performed when the blade in the coupe methodology experiences blunting, or when the coupe test has reached over 60 cycles. This test is also recommended for gloves containing metal, as previously this could trigger a false result in the coupe method of testing.

This blog will explain the testing methodology and what each letter in the performance table represents.

Testing Method

Before the test is carried out, a number of preliminary tests are carried out. This involves a number of cuts using a variety of masses which are applied to the blade. This typically includes:

- Five cuts in the range of 5-15mm

- Five cuts in the range of 15-30mm

- Five cuts in the range of 30-50mm

Following this, a scatter graph is drawn by plotting stroke length against the applied load.

From this graph, an estimate is calculated for the weight required for the blade to travel a 20mm distance before cutting through the sample, by plotting a trend line through the data points.

At this point, a further five test cuts are carried out and the graph is re-plotted.

If the average of these five cuts is within a suitable tolerance of 20mm (give or take 2mm), an estimate is taken from the graph and recorded as the final result.

If the average of the five cuts is outside of the referenced tolerance, the new estimate is used for five more cuts, with the results used again for the final re-plot. Then, the final estimate from the third graph is the test result.

Therefore, in brief terms, the performance level is based on the estimated force required to generate a 20mm stroke, measured in Newtons.

This force simulates pressure against the blade in a ‘real-life’ scenario.

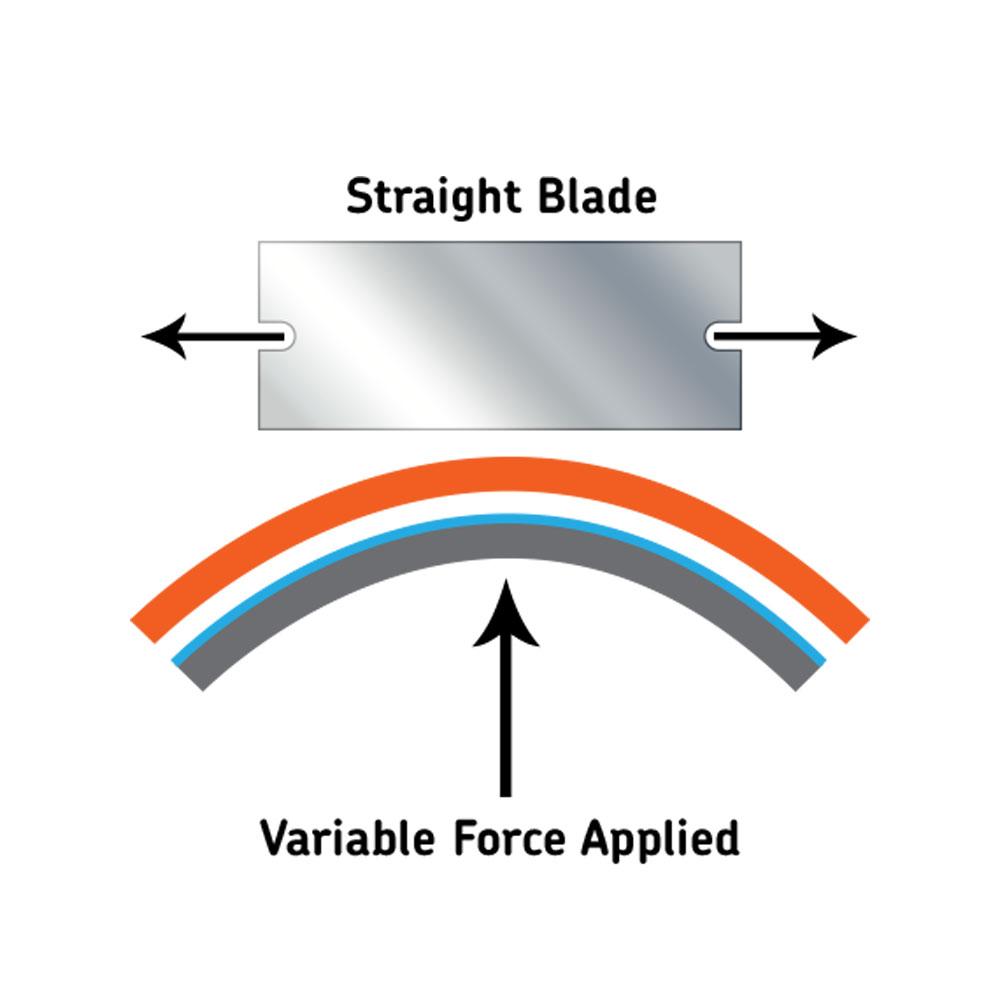

You can see an illustration of the test method below:

| Performance Level | Weight (Newtons) |

|---|---|

| A | 2 |

| B | 5 |

| C | 10 |

| D | 15 |

| E | 22 |

| F | 30 |

Differences between the Coupe and ISO13997 tests

Besides the two tests being performed on different machinery, one difference between the Coupe and ISO13997 test is the blade and how it is used. In the Coupe methodology, a single round blade is used until the product is cut through (triggering the end of the test on that sample), whereas, in the ISO13997 test, the straight blade only travels across the sample once before being replaced with a fresh blade. This eliminates the risk of the blunting of the blade in the test, which was previously an issue in the Coupe test.

The test is ended once the force is great enough to cut through the test fabric; making contact with the metal testing unit which, in turn, generates an ‘electrical-contact’.

For gloves which contain steel/metal fibres, a plastic film is placed between the testing unit and the sample being tested. This is to prevent a false reading, which was a common occurrence for products such as these in the Coupe test.

If you are interested more information on the above standard, or on any of our cut-resistant gloves, you can contact us via the below:

Call – 01653 617718

Email – sales@just1source.com