How to Choose Gloves for Maximum Safety and Protection

In industries where hand safety is paramount, effective glove selection is crucial to ensure maximum safety and protection. Individuals responsible for selecting protective gloves must consider several factors to cater to specific work environments. A proper understanding of glove material is essential as different materials offer varying levels of resistance and protection. For instance, resistant gloves made from nitriles provide superior defence against solvents and oils, while natural rubber gloves may be preferred for their elasticity and comfort. The process of choosing gloves also demands attention to glove type, ensuring the glove’s design aligns with the task at hand.

While disposable gloves might be sufficient for short-term exposure, more robust safety gloves are necessary for extended contact with harsh substances. Additionally, the prevalence of latex allergies necessitates the exploration of alternative materials to prevent allergic reactions among glove users. It’s essential to remain mindful of such health concerns when you’re in the phase of glove selection.

Prioritising hand protection means not only selecting protective gloves that shield from immediate hazards but also considering the long-term well-being of the wearer. The glove material should afford comfort without compromising on the protective qualities. Whether you’re engaging in hazardous materials handling or routine tasks, the right selection of protective gloves can make all the difference in fostering a safe and productive work environment.

Essential Factors to Consider When Selecting Protective Gloves

When it comes to ensuring on-the-job safety, selecting protective gloves is paramount. The right glove type can mean the difference between a safe day at work and an injury that could have been avoided. It’s not just about picking any safety gloves; it’s about equipping workers with a glove material that offers adequate hand protection. As you begin the process of selecting gloves, you must consider various factors.

Firstly, it’s essential to identify the risks present in your workplace. Whether it’s chemical exposure or sharp objects, each hazard demands a specific type of resistant gloves. For industries dealing with hazardous materials, work gloves that provide a robust barrier against chemicals and punctures are a necessity. On the other hand, for tasks that require single-use options, disposable gloves would be the suitable pick. Ensure the glove selection caters to the tasks at hand.

Additionally, pay attention to the glove material—nitrile, latex, or neoprene, each offer different levels of protection and comfort. And don’t forget to consider any potential latex allergies among the workforce; alternative materials might be necessary. Lastly, when you choose gloves, ensure they fit well and provide the dexterity needed for precise work. Proper glove selection is vital, not just for compliance, but for fostering a culture of safety where accidents are minimised through the right selecting protective gloves practices.

The Importance of Glove Sizing in Ensuring Hand Safety

Glove sizing is a critical consideration in the pursuit of hand protection within various work industries. A glove’s fit determines not only comfort but also the level of safety it provides. When selecting protective gloves, attention must be given to ensuring a snug fit, allowing for dexterity without compromising on the glove material’s protective qualities. Ill-fitting safety gloves can be more than just uncomfortable; they can detrimentally impact a worker’s performance and expose them to risks, negating the benefits of hand protection. To choose gloves that offer optimal protection, it’s essential to evaluate glove sizing charts and understand the measurements relevant to your specific needs.

In the context of work gloves, selecting gloves that align with the hazards of your industry is paramount. Whether you’re dealing with hazardous materials or require resistant gloves for mechanical tasks, glove sizing plays a pivotal role. Incorrectly sized gloves may lead to exposure or reduced grip, increasing the likelihood of accidents. Consequently, a rigorous glove selection process is imperative, factoring in not only glove material and design but the size and fit for each user.

Moreover, glove fit is not just about glove sizing; it also encompasses how the glove conforms to the nuances of hand movements – a critical component when you need to perform precise tasks. The art of how to choose gloves extends to comprehending the various materials and their respective benefits, such as chemical or heat resistance. By understanding the importance of accurate glove sizing and appropriate material selection, workers can ensure enhanced hand safety and maintain high productivity levels. It’s not just about donning protective gloves; it’s about selecting gloves that will stand as a reliable barrier between your hands and the potential dangers of the job.

Know the EN Standards for Safety Gloves in Work Industries

Understanding the EN Standards is crucial when selecting safety gloves for various work industries. These regulatory standards provide a framework for glove selection, ensuring that protective gloves meet specific criteria for hand protection. When handling hazardous materials, it’s imperative that the safety equipment used, such as resistant gloves, conforms to these standards to guarantee maximum safety and protection. The EN Standards cover various aspects of safety gloves, including resistance to abrasions, cuts, heat, chemicals, and more, ensuring that glove material is tested and certified for specific risks in work environments. Moreover, the correct glove standards help workers in identifying gloves that offer the right level of protection for the tasks at hand.

By familiarising oneself with these EN Standards, those responsible for safety in work industries can make informed decisions about glove selection. The standards also help in understanding the capabilities and limitations of different glove materials, which contributes to enhanced hand protection. For instance, when dealing with different chemical or mechanical risks, knowing the protective gloves’ rating can prevent injuries and enhance compliance with safety protocols. The EN Standards further emphasise the importance of glove sizing, as a properly fitted glove is essential for comfort and functionality, preventing accidents related to poor fit.

Ultimately, incorporating the glove standards into the glove selection process is a best practice for workplace safety. By selecting gloves that align with EN Standards, industries underscore their commitment to safeguarding the wellbeing of their workers and ensuring reliable hand protection in various operational scenarios.

Identifying the Right Glove for Chemical Hand Protection

When it comes to ensuring chemical hand protection, understanding how to select protective gloves tailored for specific hazards is crucial. A multitude of industries rely on the right glove material for safeguarding workers against chemicals. Selecting the appropriate resistant gloves isn’t just about safety; it’s about maintaining productivity and glove standards. Whether you’re dealing with caustic chemicals or simply performing routine clean-up, disposable gloves may seem like a convenient option, but they may not always offer the needed protection.

Finding the right glove type is a nuanced process. Latex allergies, for instance, necessitate alternatives; thereby, understanding the glove material composition is essential. It’s important to note that different materials offer varying levels of protection. For example, nitrile gloves are known for their puncture resistance and chemical inertness, making them a popular choice for chemical hand protection. On the other hand, neoprene and PVC gloves are also viable resistant gloves for handling certain chemicals, providing adequate barriers against potential hazards.

It’s also imperative to consider the various glove standards that apply to safety gloves. These standards, such as the EN norms discussed previously, guide users in choosing gloves that meet rigorous safety criteria. Regardless of the glove selection, ensuring the right fit is part of essential hand protection. Ill-fitting gloves can compromise dexterity and safety, which is why glove sizing must never be overlooked. With these considerations in mind, workers can confidently handle hazardous materials, armed with the knowledge that their safety gloves are up to the task of protecting them against the dangers they face daily.

Protective Measures: Choosing Gloves for Mechanical Hazards

In the realm of safety equipment, providing adequate hand protection is crucial, particularly against mechanical hazards that workers face in various industries. Selecting gloves that can withstand the rigorous demands of mechanical work is vital to ensure the well-being of employees. To select protective gloves, it’s essential to consider the specific resistant gloves needed for tasks involving abrasions, cuts, vibrations, and punctures. The glove’s material and design are integral parts of this selection process, as they determine the level of protection provided.

When considering glove selection for mechanical hazards, one must assess the glove type that aligns with the occupational risks present. The durability and functional integrity of protective gloves are often dictated by the glove material, ranging from leather and cotton blends to advanced engineered fibres promising heightened resistance. Additionally, the use of safety gloves that are engineered to enhance grip without sacrificing protection can mitigate the risks involved with handling heavy or slippery objects.

Work environments continuously evolve, and so does the need for safety gloves that cater to various applications. From selecting gloves for construction workers to ensuring the hand safety of assembly line operators, the glove selection process is a testament to the commitment towards occupational safety. It’s imperative to know the EN standards when selecting gloves, as these guidelines help to identify glove efficacy against specific mechanical hazards. Moreover, selecting the right glove type and accompanying glove material isn’t just about safety; it also impacts productivity and job satisfaction.

To sum up, the process of selecting gloves for mechanical hazards melds practicality with stringent safety considerations, ensuring every pair of work gloves stand up to the industry’s demands while providing comprehensive hand protection.

Multi-hazard Protection: Selecting Gloves That Offer Comprehensive Safety

When engaging in high-risk industries, ensuring multi-hazard protection is imperative, especially for your hands. Selecting gloves with comprehensive safety features is not just an option, it’s a necessity for workplace safety. When choosing gloves, the complexity lies in identifying protective gloves that safeguard against various risks. Whether it’s for construction, chemical processing, or mechanical work, select protective gloves that deliver robust defence against a spectrum of hazards. The glove material plays a pivotal role in this selection process, as certain materials provide enhanced resistant gloves for specific risks.

Of course, the glove selection goes beyond picking the right material; understanding the glove’s compatibility with different safety equipment is also crucial in ensuring hand protection. Integrating work gloves as part of a larger safety outfit requires careful consideration to avoid any gaps in safety coverage. With appropriate guidance, you can excel in choosing gloves tailored to the nuances of your specific work environment.

Consideration of safety gloves within the realm of multi-hazard protection must also acknowledge standardised benchmarks for safety. Know the EN standards for safety gloves to ascertain that your selection upholds stringent protective measures. The ability of gloves to withstand mechanical hazards, as well as offer chemical hand protection, is vital. It’s about more than just selecting gloves; it’s about ensuring every aspect of hand safety is comprehensively covered. By meticulously implementing these criteria into your choice process, you can be confident in achieving the utmost glove material efficacy and hand safety for your workforce.

Selecting Gloves for Thermal Hazards: Hot and Cold Conditions

When choosing safety gloves for thermal hazards, understanding the extremities of hot conditions and cold conditions is crucial for ensuring **hand protection**. Selecting gloves that are designed to withstand these specific conditions can mean the difference between safety and injury in work industries. Protective gloves for thermal hazards should be made from materials that offer insulation against heat and cold while maintaining comfort and dexterity. Glove selection for hot environments often requires resistant gloves that can handle high temperatures without degrading, melting, or burning. Similarly, gloves for cold environments should shield the hands from frostbite and decreased mobility.

When it comes to work gloves mitigating thermal risks, the glove material is paramount. Materials such as leather, terrycloth, or aluminised fabrics are effective for heat-resistant gloves, whereas insulated and moisture-wicking fabrics are suited for cold-resistant gloves. **Glove type** can vary from mitts for extreme temperatures to coated fabrics for handling cold objects. The **glove material** and the design will be dictated by the specific application and the temperature range encountered.

Effective **glove selection** is a central component of your **safety equipment** strategy. Selection decisions should also integrate knowledge of the EN Standards for safety gloves, ensuring compliance with requisite industry benchmarks for thermal protection. Whether you’re faced with **hot conditions** or **cold conditions**, selecting the right safety gloves can safeguard workers’ hands from significant thermal risks. It’s not just about the glove type; it’s about matching the protective gloves to the specific thermal hazards you encounter in your field.

Glove Cuff Styles and Their Role in Safety Gloves Selection

When choosing gloves specifically designed for work industries, it’s crucial to not overlook the importance of glove cuff styles. The cuff of a glove greatly contributes to overall hand protection, influencing both safety and comfort during use. The selection process for protective gloves must carefully consider cuff length, as it can determine the extent of protection against various hazards. Whether dealing with extreme temperatures, sharp objects, or hazardous materials, selecting gloves with the appropriate cuff style can significantly enhance user safety.

The role of glove cuff styles extends to securing the glove on the wearer’s hand, which aids in preventing debris from infiltrating and causing discomfort or injury. Longer cuffs offer additional coverage and are preferred in industries where forearm protection is necessary. Short cuff gloves, on the other hand, provide ease of movement and are suitable for tasks requiring high dexterity. When it comes to glove material, workers must find a balance between resistant gloves that can withstand the work environment’s severity and the flexibility required for the task at hand.

Understanding glove cuff styles is a fundamental aspect of glove selection, as they play a pivotal role in ensuring proper hand protection for labourers across various work industries. When selecting gloves, it is essential to match the glove’s protective qualities with the specific needs of the task, which includes considering the potential contact with hazardous materials or mechanical hazards. Incorporating the right glove cuff style not only optimises safety but also enhances overall work efficiency.

Choosing the right gloves to protect skin: a guide for employers

Protecting against substances in the workplace

The most effective and reliable way to prevent skin problems is to design and operate processes to avoid contact with harmful substances. So take all the steps you can to achieve this before resorting to the use of protective gloves.

Protective gloves tend to be less effective than other control measures but if avoiding contact is impractical or is not enough to protect employees then gloves may be needed. When you select protective gloves, base your choice on the work, the wearer and the environment they work in. You need to consider the following five factors:

- Identify the substances handled.

- Identify all other hazards.

- Consider the type and duration of contact.

- Consider the user – size and comfort.

- Consider the task.

Identify the substances handled

Gloves differ in design, material and thickness. No glove material will protect against all substances and no gloves will protect against a specific substance forever.

Water/’wet work’

- Prolonged or frequent contact with water, particularly in combination with soaps and detergents, can cause dermatitis. ‘Wet work’ is the term used to describe tasks in the workplace that can cause this.

- To protect the hands from ‘wet work’ choose a glove that meets the European Standard EN374-2. This shows that the gloves are waterproof.

Substances in products, created by work processes and ‘natural’ substances

- Substances in products. Some products contain substances that can harm the skin or enter the body through skin contact. The product label or material safety data sheet should tell you if this is the case. These may also give information on what protective gloves to use. If this is missing then try contacting the product supplier or manufacturer for help.

- Substances created by work processes and ‘natural’ substances. Not all harmful substances come in labelled containers. Substances can be generated during work activities (eg wood dust from sanding, solder fumes). Remember that handling some ‘natural’ substances like foods and flowers can cause skin problems too. If you are unsure if a substance produced by a work process or a natural substance you are handling is harmful, you can get help from a variety of sources, eg your trade association or this website.

- To protect hands from substances/chemicals choose a glove that meets the European Standard EN374-3. But make sure the glove material you choose protects against the substances being handled.

- Glove manufacturers usually produce charts to show how well their gloves perform against different substances. Manufacturers use three key terms, breakthrough time, permeation rate and degradation:

- Breakthrough time is the time a chemical takes to permeate through the glove material and reach the inside. Permeation is a process by which a chemical can pass through a material without going through pinholes or pores or other visible openings. This tells you how long you can use a glove for.

- The permeation rate is the amount that then permeates through. The higher the rate the more of the chemical will move through the glove. Choose a low rate.

- Some chemicals can destroy the glove material. It may get harder, softer or may swell. Degradation indicates the deterioration of the glove material on contact with a specific chemical. Choose gloves with an excellent or good degradation rating.

- You can use manufacturers’ charts to identify the best gloves for the chemicals being handled or glove manufacturers can help with this step.

- The performance of glove materials can vary slightly from manufacturer to manufacturer, so base your selection on the correct manufacturers’ data.

- Keep in mind that the manufacturers’ data is for pure chemicals, not mixtures. When you mix chemicals, their properties can change. As a rule of thumb, base your glove selection on the component in the mixture with the shortest breakthrough time. However, the only way to be absolutely sure that a glove performs well against the mixture is to have it tested.

- Some people develop an allergy to gloves made of natural rubber latex. Choose non-latex gloves unless there are no alternatives that give the protection needed. If you must use latex, choose low-protein, powder-free gloves.

Identify all other hazards for hands

Identify any other hazards present. For example, is there a risk of, abrasion, cuts, puncture or high temperature? There are chemical protective gloves that also give protection against mechanical hazards (those marked EN388) and thermal hazards (those marked EN407).

Consider the type and duration of contact

- Will gloves be worn for a short time intermittently or for long periods? Comfort is more important for longer wear. Generally, thicker, robust gloves offer greater protection than thinner gloves but thinner gloves offer better dexterity.

- Will contact be from occasional splashes or by total immersion? Short gloves are fine to protect against splashes. If hands are immersed (and you can justify that this is unavoidable), choose a length greater than the depth of immersion.

Consider the user – size and comfort

- Gloves should fit the wearer. Tight gloves can make hands feel tired and loose their grip. Too large gloves can create folds; these can impair work and be uncomfortable. It can help to use sizing charts.

- Comfortable gloves are more likely to be worn. Involve employees in the selection process and give them a reasonable choice to pick from. This can sometimes promote buy-in to wearing them.

- Hands can sweat inside gloves making them uncomfortable to wear. Getting staff to take glove breaks, removing gloves for a minute or so before hands get too hot and sweaty, can help air the hands. You could also consider supplying separate cotton gloves to wear under protective gloves. These can increase comfort by absorbing sweat. They can be laundered and reused.

Consider the task

- Gloves should not hamper the task. If wet/oily objects are handled, choose gloves with a roughened/textured surface for good grip. Select gloves that balance protection with dexterity. Ensure the gloves selected meet any standards required for the task, eg sterile gloves, food grade gloves. Consider whether colour is important, eg to show up contamination.

Once you have selected your gloves tell your employees how to use them properly to protect themselves. Tell them when they should be replaced, and if they are reusable gloves ask them to rinse them before removal (if practical) and tell them how they should be stored. Review their use periodically and get employee feedback, this can help check that the gloves are performing properly.

The above information has been taken from the (HSE) Health and Safety Executive

More information can be found by visiting the guidance article “Choosing the right gloves to protect skin: a guide for employers“.

Understanding Mechanical Standards EN ISO 21420:2020

General Requirements For Gloves

The new general requirements standard for protective gloves. This standard has superseded EN 420:2003+A1:2009 and has been adopted by ISO to become a worldwide standard. Some of the key requirements listed under this standard are glove design and construction, chemical innocuousness, comfort and efficiency (sizing and dexterity) and information supplied by the manufacturer.

The protective gloves must not impair performance of the activity, while providing adequate protection from risk.

The materials present in the gloves must not, under foreseeable conditions of normal use, release substances generally known to be toxic, toxic to reproduction, carcinogenic, mutagenic, allergenic, corrosive, sensitising or irritating.

Requirements include:

- Chromium VI – applicable to all leathers; less than 3mg/kg

- PH value – applicable to all materials; requirement: pH value is to be greater than 3.5 and

- less than 9.5. Each material must be tested separately

- Azo colourants – applicable to all dyed leathers and textiles; requirement: less than 30mg/

- kg for each of the carcinogenic aromatic amines listed in the analysis methods

- Dimethylformamide (DMFa) – applicable to all materials containing polyurethane (PU); less than 1,000mg/kg (1 per cent w/w)

- Polycyclic aromatic hydrocarbons (PAHs) – applicable to rubbers and plastics in direct

- contact with the skin; less than 1mg/kg of each of the eight restricted PAHs.

Specific details of any substance used in the glove which is known to cause allergies must be listed.

Sized by reference to an agreed common European hand size, for example, minimum length.

Hands Protected: Work Perfected

just 1 Source & Supply Ltd

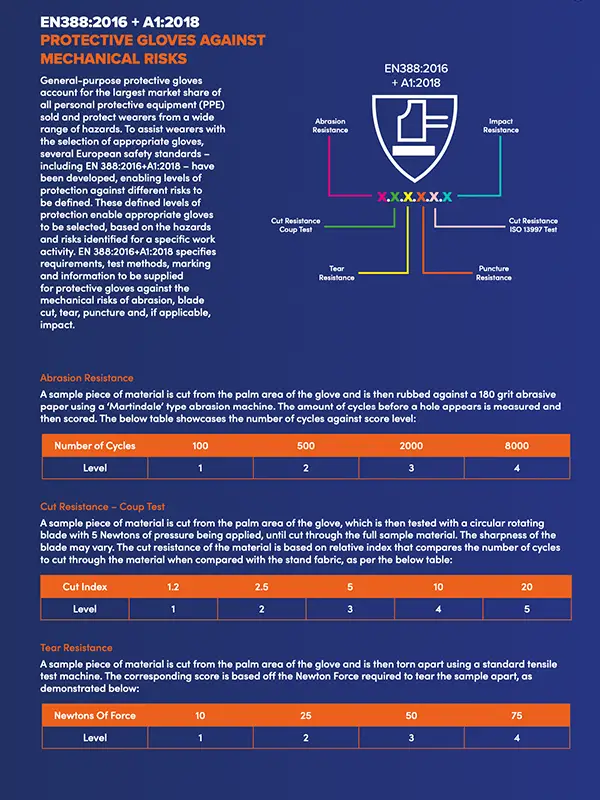

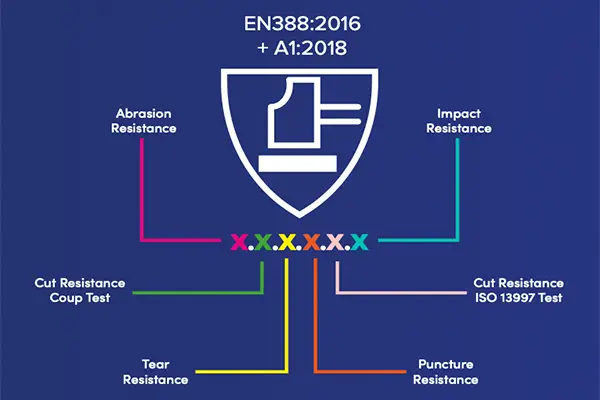

EN388:2016 + A1:2008

Protective Gloves Against Mechanical Risks

General-purpose protective gloves account for the largest market share of all personal protective equipment (PPE) sold and protect wearers from a wide range of hazards. To assist wearers with the selection of appropriate gloves, several European safety standards – including EN 388:2016+A1:2018 – have been developed, enabling levels of protection against different risks to

be defined. These defined levels of protection enable appropriate gloves

to be selected, based on the hazards and risks identified for a specific work activity. EN 388:2016+A1:2018 specifies requirements, test methods, marking and information to be supplied

for protective gloves against the mechanical risks of abrasion, blade

cut, tear, puncture and, if applicable, impact.

Abrasion Resistance

A sample piece of material is cut from the palm area of the glove and is then rubbed against a 180 grit abrasive paper using a ‘Martindale’ type abrasion machine. The amount of cycles before a hole appears is measured and then scored. The below table showcases the number of cycles against score level:

| Number of Cycles | 100 | 500 | 2000 | 8000 |

|---|---|---|---|---|

| Level | 1 | 2 | 3 | 4 |

Cut Resistance – Coup Test

A sample piece of material is cut from the palm area of the glove, which is then tested with a circular rotating blade with 5 Newtons of pressure being applied, until cut through the full sample material. The sharpness of the blade may vary. The cut resistance of the material is based on relative index that compares the number of cycles to cut through the material when compared with the stand fabric, as per the below table:

| Cut Index | 1.2 | 2.5 | 5 | 10 | 20 |

|---|---|---|---|---|---|

| Level | 1 | 2 | 3 | 4 | 5 |

Tear Resistance

A sample piece of material is cut from the palm area of the glove and is then torn apart using a standard tensile test machine. The corresponding score is based off the Newton Force required to tear the sample apart, as demonstrated below:

| Number of Force | 100 | 250 | 500 | 75 |

|---|---|---|---|---|

| Level | 1 | 2 | 3 | 4 |

Puncture Resistance

A sample piece of material is cut from the palm area of the glove, with a defined stylus applied with varying degrees of force until successfully penetrated. The amount of Newtons of force required to penetrate the material is then logged as below:

| Newtons of Force | 20 | 60 | 100 | 150 |

|---|---|---|---|---|

| Level | 1 | 2 | 3 | 4 |

Cut Resistance (ISO 13997)

A sample piece of material is cut from the palm area of the glove, with a straight blade run against this with varying degrees of force. After each cut the blade is replaced and the amount of Newtons of Force is increased as per below:

| Newtons of Force | >20 | >50 | >100 | >150 | >22 | >30 |

|---|---|---|---|---|---|---|

| Level | A | B | C | D | E | F |

Impact Resistance

Other than the fingers, each area where impact protection is claimed shall be tested for impact attenuation by measuring the peak transmitted force. The area of protection from the glove is secured over a domed anvil and is impacted at an energy of 5J. This is a pass or fail test and can be represented with either a P (Pass), X (Fail), No marking (Not tested).

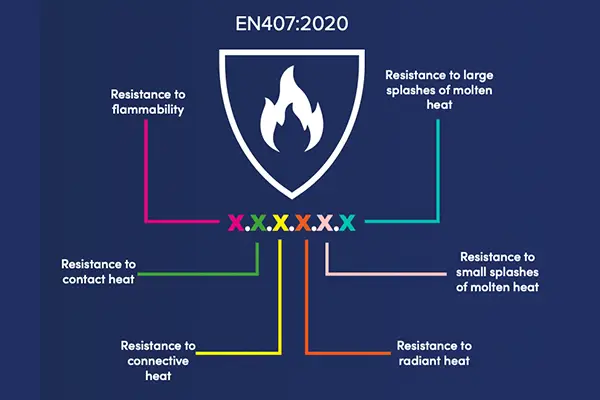

EN407:2020 Protective Gloves Against Thermal Standards

Many workers – such as those in manufacturing operations, foundries or catering kitchens – are exposed to thermal risks while undertaking their job. It may not be possible to simply remove these thermal hazards, and in such circumstances suitable personal protective equipment (PPE), which may include protective gloves (often made from leather), will need to be provided

to the worker to protect him or her from injury. This Standard is used for all gloves and other protective equipment which protect the hands, part of the hand or arm against heat and/or fire in one or more of the following forms: flames, contact heat, convective heat, radiant heat, small splashes of molten metal or large quantities of molten metal.

Resistance of Flammability

The material of the glove is stretched with a gas flame held against the material for 15 seconds. After the flame is removed from the material, the length of time taken for the material to stop burning/glowing is recorded as per below table:

| Test | Measured In | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|---|

| After-burn time | Seconds | <15 | <10 | <3 | <2 |

| After-glow time | Seconds | Infinity | <120 | <25 | <5 |

Resistance to Contact Heat

The material of the glove is exposed to a temperature range of 100°C – 500°C. The time taken for the material on the inside of the glove to increase by 10°C (From starting temperature of approx. 25°C) is then measured. The minimum amount of time accepted is 15 seconds.

| Test | Measured In | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|---|

| Contact Heat | Temp in C after 15 seconds | 100 C | 250 C | 350 C | 500 C |

Resistance to Convective Heat

The palm of the glove (and any other sample material if expected to be exposed to contact heat) is exposed to a heat source. The thermal insulation of the glove is measured by the rate of temperature rise of a calorimeter on the inside of the glove while the glove outer is placed in contact with a controlled gas flame. They are then scored on the heat transfer index detailed below:

| Test | Measured In | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|---|

| Convective Heat | Seconds | <4 | <7 | <10 | <18 |

Resistance to Radiant Heat

The material of the glove is put into a free-standing frame and the time for temperature rises of 12°C and 24°C are then measured by a calorimeter, recorded, and are expressed as radiant heat transfer indexes. The percentage heat transmission factor is calculated from the temperature rise data. See below:

| Test | Measured In | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|---|

| Radiant Heat | Heat Transfer t24 (S) | <7 | <20 | <50 | <95 |

Resistance to small splashes of molten metal

Drops of molten metal (0.5g) are put onto the glove, with the temperature inside of the glove measured. Once the temperature increases by 40°C the test is stopped and score recorded. There should be no melt through on the inner layer.

| Test | Measured In | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|---|

| Drops of Molten Metal | Number of drops | >10 | >15 | >25 | >35 |

Resistance to large splashes of molten metal

The material is tested by pouring defined quantities of molten metal onto the test specimen which is supported at an angle to the horizontal. Following pouring, damage is assessed by visual examination of an embossed thermoplastic polyvinyl chloride (PVC) sensor film placed directly behind and in contact with the test specimen during the test. Any adherence of the test metal to the surface of the glove is also recorded, and material assemblies which ignite during the test do not meet the requirement of this standard. Innermost layers of the glove are to be inspected, and must show no sign of melting and holing. Performance levels detailed below:

| Test | Measured In | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|---|

| Molten Metal | Gram | 30 | 60 | 120 | 200 |

“It is a pleasure to support and work in conjunction with some of the leading distributors in the UK and Ireland, with this being underpinned by our membership of BSiF, and their Registered Safety Supplier Scheme.”

Graham Murray – Just 1 Managing Director

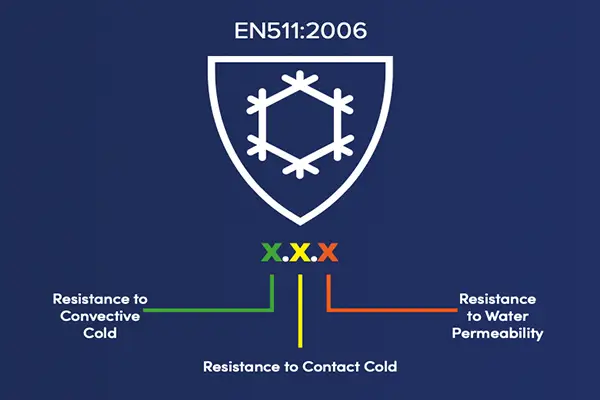

EN511:2006 Protective Gloves Against Thermal Standards

Hands are an important part of our anatomy, and are critical for virtually every activity – from driving a vehicle to operating a keyboard. However, the uses to which we put our hands mean that they are frequently exposed to the risk of injury. Furthermore, as one of the extremities of the body, our hands are also particularly vulnerable to hostile environments such as cold climates. It can be difficult or impossible to remove the hazard and, therefore, it is often more practical to provide some form of hand protection.

Resistance to Convective Cold

This ten minute test involves the glove being placed on a simulated hand that measures the amount of power required to maintain a temperature between 30°C and 35°C in a controlled environmental chamber. The chamber is cooled down to 20°C below that of the heated hand and constant air flow is applied. The test awards a performance level based on the amount of electrical power required to maintain this constant temperature.

| Performance Level | Thermal Insulation (TR) in m2C/W |

|---|---|

| Level 1 | 0.10 ITR<0.15 |

| Level 2 | 0.15 ITR<0.22 |

| Level 3 | 0.22 ITR<0.30 |

| Level 4 | 0.30 ITR |

Resistance to Contact Cold

The contact cold resistance test involves placing a piece of the glove taken from the palm side of the fingers between a hot (maintained at a temperature between 31 – 35°C) and cold metal plate. The sample is left for 30 minutes, after which the thermal resistance is calculated by determining the difference in temperature between the inner and outer surface of the glove sample.

| Performance Level | Thermal Insulation (R) in m2C/W |

|---|---|

| Level 1 | 0.025 R<0.050 |

| Level 2 | 0.050 R<0.100 |

| Level 3 | 0.100 R<0.150 |

| Level 4 | 0.150 R |

Resistance to Water Permeability

The water permeability test involves water permeating the fabric of the glove after 5 minutes of submersion. Unlike the other two EN 511 tests, the water penetration test is a pass/fail test. If the glove retains its permeability, then it passes with a Level 1 rating, while gloves that fail will receive a Level 0 rating.

Resistance to Convective Heat

The palm of the glove (and any other sample material if expected to be exposed to contact heat) is exposed to a heat source. The thermal insulation of the glove is measured by the rate of temperature rise of a calorimeter on the inside of the glove while the glove outer is placed in contact with a controlled gas flame. They are then scored on the heat transfer index detailed below:

| Test | Measured In | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|---|

| Convective Heat | Seconds | <4 | <7 | <10 | <18 |

Do you require help understanding EN Standards? Contact us

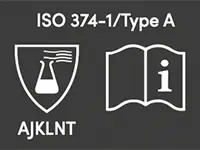

EN372 Protective Gloves Against Chemicals And Micro-organisms

EN374-1:2016+A1:2018

This testing covers the terminology and performance requirements for gloves with chemical protection. It also includes a list of 18 chemicals, whose code letters can be used on the glove marking to give a general indication on protection. Permeation testing is carried out using EN 16523-1. Three different types of performance level are defined and are shown below:

| Code | Chemical | Code | Chemical | Code | Chemical |

|---|---|---|---|---|---|

| A | Methanol | G | Diethlamine | M | Nitric acid 65% |

| B | Acetone | H | Tetrahydrofuran | N | Acetic acid 99% |

| C | Acetonitrile | I | Ethyl acetate | O | Ammonium hydroxide 25% |

| D | Dichloromethane | J | n-Heptane | P | Hydrogen peroxide 30% |

| E | Carbon Disulphide | K | Sodium hydroxide 40% | S | Hydroflouric acid 40% |

| F | Toluene | L | Sulphuric acid 96% | T | Formaldehyde 37% |

EN374-2:2019+A1:2018

This testing covers penetration, which for this process is defined as the movement of a chemical through a material, seam, pinhole, or other imperfection when tested. There are two tests which are utilised for this section of testing; the air leak test where a glove is inflated under water (with any leaks being noted) and the water leak test where a glove is filled with water (with any leaks being noted).

EN 16523-1:2015+A1:2018 (Formerly EN374-3)

This specifies a test procedure to determine the resistance of protective glove materials to permeation by potentially hazardous non-gaseous chemicals under the conditions of continuous contact. Permeation is the process by which a chemical moves through a protective glove material on a molecular level. Gloves are classified according to the breakthrough time of the chemical through the glove material.

A sample of the glove material is placed in contact with a challenge chemical and the rate at which this chemical travels through (permeates) the material is determined. The breakthrough time is the time at which this permeation rate exceeds 1μg/cm2/ min.

The samples are assigned performance levels depending on this breakthrough time. In order to be certified as chemically protective, the gloves must achieve one of three specified levels of protection defined in terms of breakthrough time and number of chemicals tested.

EN374-4:2019+A1:2018

This testing covers degradation, which is a change in glove material, typically swelling, change in appearance, or hardening. The results are expressed in a percentage format where a positive number indicates the material is weaker after testing and a negative number indicates the material has hardened during testing.

EN374-5:2016+A1:2018

This part of ISO 374 specifies the requirements and test methods for protective gloves intended to protect the user against micro-organisms. Penetration testing is required as per EN374-2, but gloves offering protection against viruses shall additionally pass a penetration test performed to ISO 16604:2004 (Determination of resistance of protective clothing materials to penetration by blood-borne pathogens).

AQL – Acceptable Quality Level

AQL is a statistical measure used to determine the level of defects that can be considered acceptable in a batch of products. For PPE gloves, the AQL 1.5 standard is required for certification, meaning only 1.5 gloves out of every 100 can have a defect. A lower AQL is better, so AQL 1 is better than AQL 1.5, and so on.

Message us: How can we help?